Leading Reasons to Pick a Reliable Pipeline Manufacturer for Your Facilities Needs

Choosing a reliable pipeline manufacturer is an essential choice that can significantly affect the success of your framework tasks. Variables such as adherence to quality control procedures, compliance with regulatory standards, and the accessibility of customized options play an important function in ensuring safety and durability. Furthermore, solid consumer support and competitive prices might even more improve the total worth proposal. As you think about these components, it becomes crucial to recognize exactly how they interconnect to develop a structure for your task's long-term practicality and efficiency. The implications of this option might be a lot more extensive than at first regarded.

Quality Assurance and Standards

Guaranteeing the stability and dependability of pipeline manufacturing is extremely important, and this begins with rigorous quality control and adherence to market requirements. A robust quality control program is important to the manufacturing of pipelines that meet the rigorous needs of framework applications. Manufacturers should execute complete testing treatments, including material examination, weld integrity assessments, and stress screening, to assure that each pipeline sector can endure operational stress and anxieties.

Conformity with sector standards, such as those stated by the American Society for Testing and Products (ASTM) and the American Petroleum Institute (API), is vital in maintaining quality. These standards include a variety of elements, including product requirements, producing procedures, and efficiency requirements, which offer as a criteria for evaluating pipeline quality.

Constant monitoring and analysis of manufacturing processes promote a society of responsibility and enhancement. By incorporating sophisticated modern technologies and methods, such as Lean Manufacturing and 6 Sigma, pipeline manufacturers can boost their quality control efforts, reducing problems and assuring peak performance. Inevitably, a commitment to quality control not only safeguards the stability of the pipes but additionally imparts confidence in stakeholders, ensuring that infrastructure demands are fulfilled successfully and securely.

Improved Safety And Security Functions

Pipeline suppliers are increasingly prioritizing improved security functions to resolve the risks and complexities related to framework tasks. In an era where safety and security policies are ending up being much more stringent, producers are buying sophisticated technologies and materials designed to minimize threats connected to pipeline installation and operation.

One popular safety function is the assimilation of leak detection systems, which make use of sensing units and keeping track of technologies to identify prospective leakages before they rise right into even more significant issues. These systems not only protect the environment yet also secure public wellness and building. Pipeline Manufacturer. Additionally, manufacturers are employing advanced materials that resist corrosion and fatigue, further lowering the chance of catastrophic failings

Additionally, lots of producers are executing extensive testing methods to ensure that pipelines can withstand severe conditions such as stress surges and seismic tasks. Considerable training programs for personnel associated with installment and upkeep enhance functional safety and security by making certain adherence to ideal methods.

The adoption of automated control systems permits for real-time tracking and feedback, offering an added layer of safety. By selecting a trustworthy pipeline manufacturer with an emphasis on improved security functions, stakeholders can substantially reduce dangers and assure the integrity of their infrastructure jobs.

Proven Sturdiness and Long Life

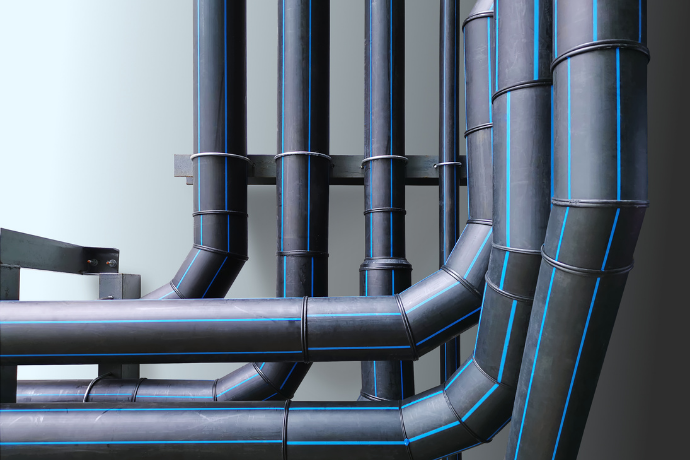

High-Quality Products Utilized

Quality materials play a crucial role in the production of reputable framework solutions. A credible pipeline manufacturer focuses on using high-grade products to assure that their products can withstand the roughness of environmental stress factors and functional demands (American Plastics LLC HDPE Pipeline Manufacturer). Products such as top-quality steel, polyethylene, and advanced composite materials are typically chosen for their remarkable stamina, corrosion resistance, and durability

The option of these materials substantially impacts the total durability of pipeline systems, which are essential for delivering different materials, consisting of gas, water, and oil. Top notch materials not only improve the mechanical residential properties of the pipelines however also add to lower upkeep costs and minimize the likelihood of failures or leaks gradually.

The usage of premium materials is critical in abiding with sector standards and policies, verifying that the framework can run successfully under numerous conditions. Inevitably, spending in pipes made from premium products equates to increased dependability and efficiency, making them a sensible option for framework tasks. Picking a manufacturer dedicated to utilizing just the best products is an important step in protecting the integrity and effectiveness of your facilities requires.

Extensive Evaluating Specifications

Exactly how can suppliers ensure the dependability and durability of their pipeline systems? The response depends on the implementation of extensive screening requirements throughout the production procedure. Trusted pipeline producers follow rigid quality control methods that incorporate various phases of manufacturing. This consists of preliminary product evaluation, in-process checks, and last item examinations to establish that every pipeline goes beyond or meets sector specifications.

One of the important facets of these screening requirements is the simulation of real-world problems. Suppliers subject their pipes to extreme stress, temperatures, and destructive settings to assess their efficiency and sturdiness. Advanced techniques, such as non-destructive testing (NDT), are employed to spot prospective problems that can jeopardize the honesty of the pipelines in time.

Modification Options Available

Customization alternatives play a crucial role in boosting the performance and viability of pipeline options when it comes to conference varied infrastructure requirements. Dependable pipeline makers recognize that one dimension does not fit all; for that reason, they use customized options to deal with specific job requirements.

Personalization options may include variants in materials, sizes, and wall thicknesses, permitting customers to choose pipelines that best suit their functional conditions. For example, producers usually supply options for corrosion-resistant finishings or specialized cellular linings, making certain longevity and reliability in difficult atmospheres. Additionally, the capability to select specific installations and connection kinds enhances the flexibility of the pipeline systems to diverse formats and configurations.

Furthermore, makers might facilitate bespoke engineering services, which allow customers to team up on layout aspects, making certain that the pipeline incorporates flawlessly with existing infrastructure. This collective method not only enhances functionality but additionally maximizes setup processes.

Eventually, by using customization choices, business can accomplish boosted effectiveness, decreased upkeep expenses, and boosted total efficiency. Picking a maker that prioritizes these options is basic for any organization seeking to develop a reliable and robust pipeline infrastructure.

Compliance With Regulations

Ensuring conformity with policies is an essential facet of pipeline production, as it safeguards both public security and environmental honesty. Pipeline producers must follow a plethora of neighborhood, national, and global criteria, which regulate different facets of design, products, construction, and functional methods. Compliance with these laws not just avoids lawful effects yet additionally improves the general reliability and safety and security of pipeline systems.

A trustworthy pipeline manufacturer will stay upgraded on the most up to date regulatory adjustments and assurance that their products satisfy or exceed these needs. This includes obtaining needed accreditations and conducting extensive screening to confirm the honesty and durability of their pipelines. For circumstances, makers must adhere to requirements established by companies such as the American Culture for Testing and Products (ASTM) and the American National Criteria Institute (ANSI), which develop benchmarks for worldly top quality and security.

In addition, adherence to ecological regulations is vital to minimize prospective environmental influences. By selecting a manufacturer dedicated to compliance, services can assure that their pipeline framework not only fulfills functional demands however likewise adds to lasting techniques and area trust. In this means, compliance functions as a structure for liable and reliable facilities advancement.

Strong Client Support

Extraordinary client assistance is a keystone of effective pipeline production, ensuring and cultivating lasting relationships customer satisfaction. A trusted pipeline manufacturer understands that resolving client needs is essential throughout the job lifecycle, from initial consultation to post-installation assistance.

Solid customer support encompasses effective interaction, prompt actions, and professional assistance. Clients ought to expect a committed team that is conveniently offered to address questions, give technical assistance, and troubleshoot concerns as they occur. This level of interaction not just enhances the customer experience however also mitigates prospective risks related to pipeline jobs.

In an affordable landscape, solid customer assistance separates a dependable pipeline manufacturer from its counterparts. By picking a manufacturer that prioritizes client connections, stakeholders can assure that their framework demands are met expertise and treatment, ultimately resulting in successful task end results.

Affordable Rates and Worth

Competitive pricing is vital for any pipeline manufacturer intending to supply economical solutions to facilities needs. By making sure that items supply long-lasting financial investment value, companies can cultivate depend on and loyalty amongst their clients. This critical strategy not just boosts customer complete satisfaction however also positions manufacturers as leaders in an open market.

Cost-Effective Solutions

In today's open market, lots of companies seek cost-effective remedies that balance high quality and affordability. Choosing a trustworthy pipeline manufacturer is important for achieving this objective. A maker that focuses on affordable prices can use significant financial savings without endangering on the stability or efficiency of their items.

Cost-effective services are not simply regarding lower rates; they incorporate the total value supplied. A trustworthy manufacturer assurances that their pipelines satisfy industry criteria and regulatory needs, which can avoid pricey rework or downtime in the future. By investing in high-grade materials and advanced manufacturing procedures, these companies can provide items with boosted sturdiness and minimized maintenance expenses.

In addition, a dependable manufacturer commonly has actually established connections with providers, permitting them to source materials more effectively and pass those cost savings on to their clients. This strategic advantage can lead to a far better rate factor for projects, making it simpler for companies to manage their budgets efficiently.

Eventually, choosing a pipe manufacturer that uses economical options allows companies to optimize their infrastructure investments while securing long-lasting operational success. This thoughtful method settings business to flourish in a progressively competitive landscape.

Long-Term Investment Worth

Buying premium pipeline solutions not just ensures immediate performance however likewise contributes to long-term worth for companies. When choosing a reliable pipeline manufacturer, companies profit from competitive pricing that mirrors truth worth of reliable and long lasting products. These suppliers focus on high quality products and cutting-edge styles, making certain that the pipelines stand up to the test of time and minimize the requirement for constant replacements or repair services.

In addition, a credible manufacturer often supplies comprehensive service warranties and support solutions, additionally improving the general worth of the investment. By picking pipelines crafted for longevity, organizations can mitigate operational disruptions and linked costs, resulting in higher performance over time.

Furthermore, with the right manufacturer, organizations can attain price savings through boosted energy effectiveness and reduced maintenance demands. This converts right into lower operational expenses, enabling better allocation of sources in the direction of various other necessary facilities tasks. Inevitably, investing in reliable pipeline services is not simply a purchase; it is a calculated choice that pays dividends with time, reinforcing the company's commitment to sustainability and operational quality.

Frequently Asked Inquiries

What Products Are Generally Made Use Of in Pipeline Production?

Pipeline making typically utilizes materials such as steel, ductile iron, polyethylene, and PVC (HDPE Pipe Supplier). These materials are chosen for their longevity, resistance to corrosion, and viability for numerous applications, guaranteeing effective and reliable transport of liquids

How Can I Confirm a Manufacturer's Reputation?

To validate a maker's track record, research study online evaluations, seek testimonials from previous customers, check market qualifications, and get in touch with pertinent specialist associations. Furthermore, evaluate their background of task distribution and adherence to security and quality standards.

What Is the Typical Preparation for Pipeline Delivery?

The typical preparation for pipeline delivery commonly ranges from six to twelve weeks, relying on aspects such as material requirements, making capacity, and order volume - Permian Basin HDPE Pipe Supplier. Timely interaction with makers can give extra specific quotes

Exist Service Warranties Available for Pipeline Products?

Yes, several reputable pipeline suppliers supply service warranties on their products. These service warranties generally cover defects in materials and craftsmanship, making certain that customers obtain reliable and resilient remedies for their facilities projects, thus boosting total task durability.

Can I Go To the Manufacturing Center Before Putting an Order?

Yes, several reliable pipeline suppliers encourage visits to their centers. This enables prospective clients to assess production requirements, quality assurance actions, and total operations, fostering openness and confidence prior to making substantial buying decisions.

Choosing a reputable pipeline manufacturer is an essential decision that can substantially affect the success of your framework projects. Pipeline makers are progressively prioritizing boosted security functions to deal with the intricacies and threats linked with infrastructure projects. A trustworthy pipeline manufacturer focuses on the usage of next high-grade products to ensure that their items can stand up to the roughness of functional needs and ecological stress factors. By regularly upgrading testing approaches and integrating innovative innovations, suppliers can assure that their pipelines are constructed to last, offering essential infrastructure that endures the examination of time. Pipeline producers need to stick to a wide variety of local, national, and worldwide requirements, which regulate various facets of layout, products, construction, and operational methods.